-

Overview

Overview

Centre Testing International Group Co., Ltd. (NG28) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in NG28’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. NG28 is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (NG28) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

QUALITY & VALUE

-

MachiningMore

MachiningMoreNG28 aviation laboratory has relatively complete aviation sample processing ability, and can design, customize and process samples for different materials (such as Ti, Ni, Al alloy) or different test items according to customer requirements. Strict process control ensures the influence of machining residual stress on test data. Provide guarantee for customer's detection from the source.

-

Mechanical TestMore

Mechanical TestMoreNG28 is able to provide a series of tests to identify and examine the performance and process properties of metal and non-metal material products.Through the test, we can help customers to evaluate the mechanical properties of materials and identify the weakness of materials (limit of use).

-

High Temperature Mechanical Test (Creep/Rupture)More

High Temperature Mechanical Test (Creep/Rupture)MoreStress fracture and creep testing methods are very important to understand and prevent product failure, and provide valuable insights into the effect of long-term stress on materials. NG28 aviation laboratory can carry out standard and improved test methods for all kinds of metal materials, especially superalloys.

Stress fracture testing and creep testing are mechanical testing services that provide manufacturers or material suppliers with key data on the performance of their products over time. In the process of testing, the material is kept under a given constant load for a period of time, and the maximum temperature is 1200 ℃ until failure occurs. In this way, our team of experts analyzes the data results to provide important data on long-term physical and thermal stresses. -

Static Mechanical TestMore

Static Mechanical TestMoreNG28 aviation laboratory has relatively complete aviation static mechanics testing ability. It has various environmental chambers, such as electronic universal testing machine, high and low temperature pendulum impact testing machine, drop hammer impact testing machine, fastener comprehensive performance testing machine and simulation assembly manipulator, composite material non-destructive testing equipment, high-temperature furnace and high-low temperature / constant temperature and humidity / salt spray / ultraviolet / sunlight simulation, various gauge extensometer, data acquisition instrument, hardness tester and other test and environmental equipment and measurement monitoring The system has a comprehensive ability to detect the static mechanical properties of metal and composite materials. It can carry out static tests in a wide load range from - 180 ℃ to 1250 ℃, drop weight and Charpy pendulum impact tests with a maximum impact energy of 300j, fastener performance and all link simulated assembly process performance tests.

-

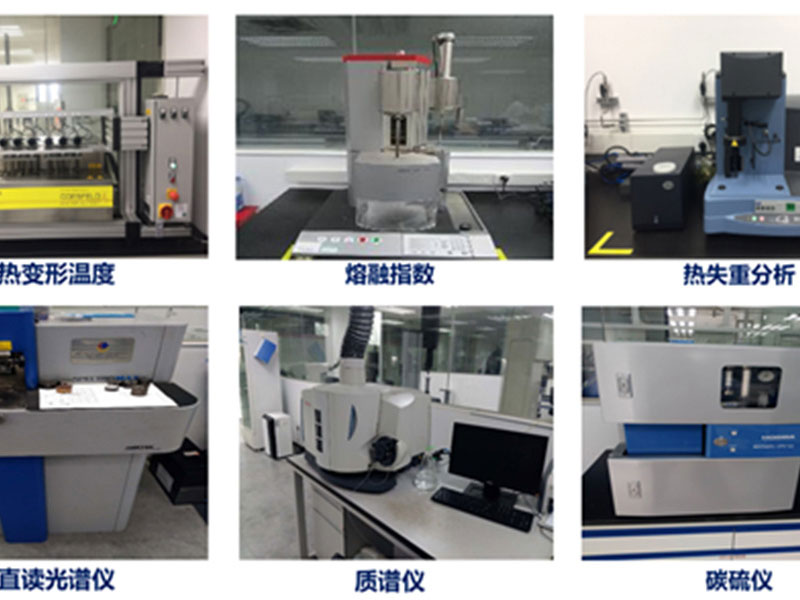

Physical and Chemical AnalysisMore

Physical and Chemical AnalysisMoreThe physical and chemical testing of materials can be applied in almost every industry. Its testing content includes a wide range of services from grain size analysis to fracture metallographic examination to composition analysis. Our team of experts can use a variety of technologies and equipment to identify material types, defects and processing errors.

Aviation manufacturers are adopting more advanced technologies to bring innovative materials to the market. Although many of the traditional physical and chemical analysis methods used to evaluate metals remain unchanged, the physical and chemical properties of materials still face unprecedented challenges.

Material physical and chemical testing focuses on the combination of mechanical testing and chemical analysis to quantify the properties of metals. Metallographic methods are often used to determine material type, grade or grain size, and to provide certification for new materials or mixed batches, microstructure analysis, and failure analysis.

- About NG28

- Our Services

- Investor Relations

- NG28 Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- NG28 Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号