-

Overview

Overview

Centre Testing International Group Co., Ltd. (NG28) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

SustainabilitySustainability is deeply rooted in NG28’s business model, by delivering science-based solutions and verification services, to increase transparency and traceability throughout the global value chain. NG28 is a proponent of carbon neutrality and sustainable development.

-

Our service

Our serviceCentre Testing International Co., Ltd. (NG28) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

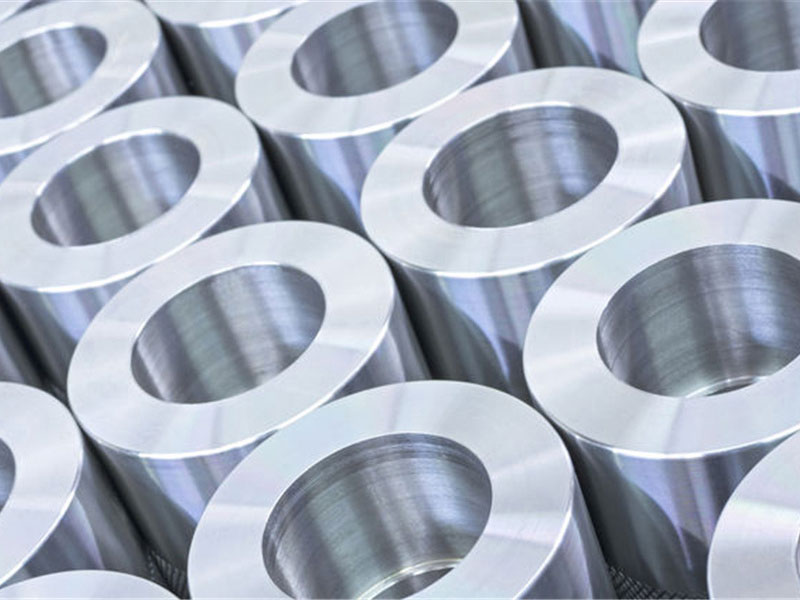

QUALITY & VALUE

Corrosion test is an inspection test to manage production process and control product quality. It is also a common method to study corrosion mechanism, select effective anti-corrosion measures and develop new corrosion resistant materials. NG28 has been deeply engaged in the field of material analysis for ten years. With solid professional knowledge, we can provide customers with comprehensive and rapid corrosion test scheme, which is helpful to solve various corrosion related problems.

- Shopping cart

- Consulting quotation

- Online shopping mall

? Service Background

- In a given environment, determining the adaptability of various corrosion prevention measures, the best choice, quality control approach and expecting after take these measures the component’s service life;

- Evaluation of corrosion resistance of materials;

- Determining the erosivity of the environment, and reseaching the effects of impurities and additives on corrosion rate and corrosion morphology;

- Reseaching the environmental pollution of corrosion products;

- It is used as reproducibility test when analyzing the failure reason of components;

- Studying the corrosion mechanism.

? Service Content

1. Routine test items

|

Salt spray test |

Neutral salt spray test (NSS), acetic acid-salt spray test (AASS), copper accelerated acetic acid-salt spray test (CASS), cyclic salt spray test, filiform corrosion, heat-resistant brine |

|

stainless steel Intergranular corrosion |

10% oxalic acid etch test for stainless steel, Sulfuric acid / ferric sulfate test for stainless steel, Sulfuric acid / ferric sulfate test for stainless steel, 65% nitric acid test for stainless steel, Nitric acid/ hydrofluoric acid test for stainless steels, 16% sulfuric acid/ copper sulfate test for stainless steel, 35% sulfuric acid/ copper sulfate test for stainless steel, 5% sulfuric acid test for stainless steel |

|

Dezincification resistance of copper alloys |

Dezincification of brass is a typical selective corrosion, that is, the active components in the alloy are selectively dissolved. Because different brass materials have different dezincification corrosion rates, the use of copper chloride can accelerate the dezincification corrosion of brass, thus producing different degrees of dezincification layer. The depth of the dezincification layer is measured by metallographic microscope. |

2. Adaptive range of product

It is suitable for metal materials and its products, automobile parts, aerospace parts, building steel structure, petrochemical industry, marine engineering, bridge grid, hardware profiles, etc.

3. Sample requirements

|

Salt spray test |

Whole piece test |

|

10% oxalic acid etch test for stainless steel |

Sample size≥30mm*30mm*3mm |

|

Sulfuric acid / ferric sulfate test for stainless steel, Sulfuric acid / ferric sulfate test for stainless steel, 65% nitric acid test for stainless steel, Nitric acid/ hydrofluoric acid test for stainless steels, 16% sulfuric acid/ copper sulfate test for stainless steel |

1. Plate / strip (section steel) Thickness T < 4mm, 80mm * 20mm * t Thickness 4mm < T, 80mm * 20mm * (3 ~ 4mm) 2. rods / wire / tube / welded pipe: L=80mm. T = t or T = 3 ~ 5mm 3. Tube 15mm < OD, 4mm ≤ t |

|

35% sulfuric acid/ copper sulfate test for stainless steel |

1. Raw material sample: ≥ 80 * 10 * (2 ~ 6) mm 2. Welding sample: ≥ 100 * (20 + 20) * (2 ~ 6) mm |

|

5% sulfuric acid test for stainless steel |

Sample surface area ≥ (10 ~ 30) cm2 |

|

Dezincification resistance of copper alloys |

Sample size ≥ 10 mm * 10 mm * 10 mm, area ≥ 100 mm2 |

4. Our Advantages

1) We have experienced technicians to provide detailed technical consultation and result analysis;

2) We have advanced high-end and automation integrated detection equipment to provide a variety of detection programs;

3) We have Complete testing and results reporting process to ensure accurate and reliable test results.

- About NG28

- Our Services

- Investor Relations

- NG28 Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- NG28 Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号