-

Overview

Overview

Centre Testing International Group Co., Ltd. (NG28) is a market leader in testing, inspection, certification, calibration, audit, training & technical services; building trust between governments, enterprises, and consumers.

-

Sustainability

Sustainability

By building a full value chain ESG governance system covering the strategic decision-making level, management execution level and business operation level, it actively practices penetrating management of ESG risk and opportunities, empowering sustainable development across the industry chain.

-

Our service

Our serviceCentre Testing International Co., Ltd. (NG28) is the pioneer and leader in the TIC Industry which provides one-stop solutions on testing, inspection, certification, calibration, audit, training & technical services.

-

By Industry

Our service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

Environment

Environment

-

Raw Material & Fuel Chemicals

Raw Material & Fuel Chemicals

-

Textiles, Apparel, Footwear & Accessories

Textiles, Apparel, Footwear & Accessories

-

Food & Agricultural Products

Food & Agricultural Products

-

Cosmetics, Personal Care & Household Chemicals

Cosmetics, Personal Care & Household Chemicals

-

Building Materials&Construction Engineering

Building Materials&Construction Engineering

-

Electronic & Electrical Appliances

Electronic & Electrical Appliances

-

Toys, Furniture & Home Decoration

Toys, Furniture & Home Decoration

-

Industrial Equipment & Manufacturing

Industrial Equipment & Manufacturing

-

Rail & Aviation

Rail & Aviation

-

Automotive & Spare Parts

Automotive & Spare Parts

-

Pharma and Medical Services

Pharma and Medical Services

-

Maritime Vessel Compliance Testing

Maritime Vessel Compliance Testing

By Industry

By IndustryOur service capabilties cover the upstream and downstream of the supply chain including textile and apparel,toys,electronic appliances,medical health,food...andother industries.

-

-

Specialty

SpecialtyComprehensively guarantee quality and safety, promote compliance and innovation, demonstrate brand competitiveness, and achieve higher quality, healthier, safer, and greener sustainable development.

-

Management

ManagementWe have established a clear governance structure in accordance with listing requirements and national regulations and policies to deal with internal and external challenges and achieve sustainable development.

-

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

Information DisclosureWe are committed to establishing normal and effective two-way communication with shareholders and investors. We have established a complete information disclosure mechanism to convey information to shareholders in a timely manner.

-

Talents Policy

Talents PolicyEnsuring the basic rights and benefits of employees;

Providing professional skills training to promote employees’ growth;

Carrying out various kinds of activities to balance employees’ work and life.

-

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

RecruitmentWelcome to join NG28 family! We are providing a platform for you to show your talents and achieve your career aspiration.

QUALITY & VALUE

Painting not only decorative but also have a certain physical and chemical properties. Most of the physical and chemical properties of painting are tested on the coating. NG28 can provide enterprises with painting physical and chemical performance test, used to predict the performance of the painting, but also can provide the scheme painting formula rectification scheme, make it more suitable for the performance of the construction process to the painting requirements.

- Shopping cart

- Consulting quotation

- Online shopping mall

? Business Challenges

1. Coating falls off, easy to scratch, weather resistance decline, how to improve?

2. Formula analysis to improve product defects and enhance product performance?

3. Increasingly tight safety and environmental protection policies?

? The service content

Ⅰ. Routine test items

|

Category |

Test item |

|

Physical properties |

Mobility and poor leveling, Fineness, Gloss, Viscosity, Solid content, pH value, Film thickness |

|

Weather resistance |

Xenon lamp aging, UV aging, Resistance to moisture and heat aging, Low temperature performance, Salt spray test |

|

Coating bonding strength, Impact resistance, Flexibility, Cup dash test, Abrasion performance, Adhesion |

|

|

Component analysis |

Qualitative and semi-quantitative analysis, Formula cracking, Formula improvement

|

|

Failure analysis |

Adhesion failure, Flake falling, blistering, White bloom, Chacking, Crack, Interlaminar detachment |

Ⅱ. Scope

Fire retardant painting, anticorrosive painting, heat insulation painting, insulation painting, building painting, putty, floor painting, wood painting, other painting

? Advantages

- Third-party testing institutions with CMA, CNAS and other qualifications at domestic and international.

- With high specification laboratory standards, experienced engineers can provide one-to-one services.

- It can provide multi-directional coating inspection service for enterprises and provide clear direction and suggestion for material improvement.

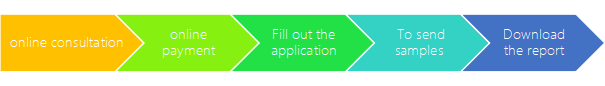

? Service Process

- About NG28

- Our Services

- Investor Relations

- NG28 Mall

-

Resource Center

- Application Forms

- Bulletin

- Training Center

- NG28 Academy

- Reports Validation

-

Join Us

- Talents Policy

- Recruitment

粤公网安备 44030602000441号

粤公网安备 44030602000441号